Transfer Release Film (Polyester Film) for Screen Printing, Offset and Digital Printing in Textile Industry

Xinhe offers heat polyester film (PET film) for both hot peel and cold peel applications in textile print industry. This polyester film features thermal stability, allowing for improved dimensional stability during high temperature applications. We have a variety of custom heat transfer films available with various surface treatments, making them suitable for CAD lettering, screen printing, off-set, flexo, and digital printing, etc. The heat stabilized polyester film is widely used as thermal transfer film printing images on T-shirts, footwears, clothes, bags and luggages.

Xinhe provides customers the heat-adhesive transfer films with a thickness of 36um, 50um, 75um, or 100um. We also use a number of slitting machines, which cut the heat adhesive transfer film into rolls or sheets according to customer requirements. Sheet sizes include 39x54cm, 64x48cm, and 50x70cm.

-

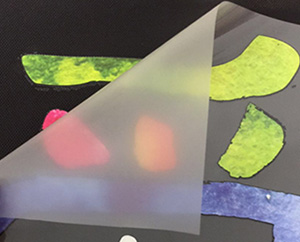

- Glossy Polyester FilmThis series of transfer film is a high gloss transfer vinyl. Patterns or logos on the clothing appear in a glossy finish after the heat transfer process...

-

- Matte FilmThis series of sublimation heat transfer film is a matte transfer film, and any patterns or loos printed using this process will feature a matte finish...

- Customers have different requirements for transfer material thickness when printing on fabric or leather. For example, when printing on leather that can’t withstand a high temperature or long term pressing, choose a thickness of 36um. The 75um thickness is another popular choice, and used for a variety of textile materials. A 100um thickness has the best temperature resistance, and can be used for printing silicone patterns.

- Transfer material thickness will affect the drying temperature of ink, and the melting temperature for adhesives and hot melt powder. If customers aren’t sure about what the right thickness for their needs is, we will prepare a range of film samples in different thickness levels for them to work with in determining their needs.

- Weather also has an impact on film release. Depending on if an environment is too wet or too cold, customers should adjust their workshop temperature.

- Folding or scratching the printed surface of film during the printing process will destroy the release coating on films, and may impact a printing effect.

- Xinhe’s Heat Transfer Vinyl should be stored in dry and ventilated environment, and has a shelf life up to 1 year.

- Xinhe can adjust the coating formula to satisfy the customization needs for the release force, thickness and any other properties.

We provide various types of vinyl transfer films for textile and leather, including T-shirt, cotton clothes, non-woven fabric and more. First, the images are printed on the surface of the film, and then we transfer the images from the film to textiles by heat pressing. We provide two types of the transfer films, one is hot peel transfer film that needs to be released in 12 seconds, and the other is cold peel transfer film. There are many models that can be applied for screen printing machines and digital printers.

Xinhe is a transfer Vinyl film manufacturer that could provide customers transfer materials with excellent printing performance, and it is specialized in the garment accessories industry and heat transfer industry. A fine transfer material will ensure their qualities from release force, tensile strength, aging strength and other details.