S716 Double Side Transfer Film

The S716 double side transfer film belongs is two-to-one model of hot peel and cold peel, with a double side matte that is printable. However, it is only applicable for screen printing processes.

For market requirements where customers want to use only a single adhesive film type to achieve both hot and cold peel, this type allows customers to arrange whichever peeling method best suits their production requirements. This transfer film has the highest matte finish among our all products, and its coating formula has been adjusted based on a previous film type, and we added new materials to improve its quality. For customers that need a cold peel, the film must be cooled before being removed after heat transfer. If a hot peel is required, the film must be removed immediately after heat transfer, which also leads to an increase in productivity.

- Printing types: screen printing

- Printing inks: oil based ink, water based ink, thermosetting ink

- Coating techniques: powder scattering, liquid adhesive coating

- Printing Equipment: automatic printing press that suitable for screen printing and Heidelberg 4-color printing press

- Applicable heat transfer materials: cottons, chemical fiber, cotton blend fabrics, EVA, non-woven fabrics, leather, and other heat resistant fabrics.

- Thickness: 36um, 50um, 75um, 100um;

- Size information: 39×54cm, 64×48cm, 50×70cm or as per customer requirements;

- Heat transfer temperature: 150 degrees or depending on the melting point of adhesives or hot melt powders used;

- Heat transfer time: 12 seconds

-

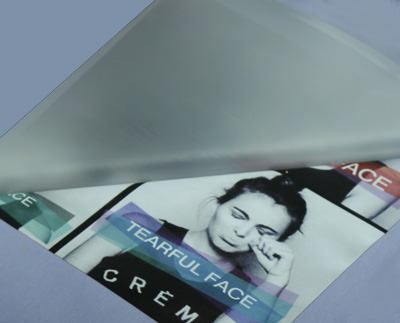

- SL-6 Heat Press Transfer FilmThe SL-6 heat press transfer film is a cold peel type, and needs to be cooled down before being removed after the heat transfer process. Users need to take care not to remove it at high temperatures

-

- SL-4P Heat Press Transfer FilmThe SL-4P heat press transfer film features a half-high gloss effect after heat transfer. By adjusting the coating proportion, we achieve a production effect somewhere between a high gloss and a matte.

-

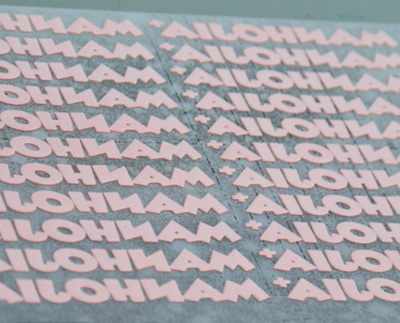

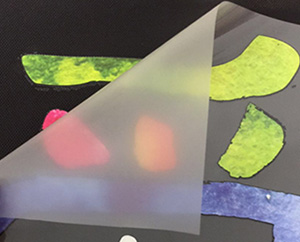

- SL-4Y Sublimation Heat Transfer VinylAfter heat transfer using the SL-4Y sublimation heat transfer vinyl, the patterns or logos on clothing feature a matte finish, much like a frosted glass surface. This protects the patterns against pollution

-

- SC-819 Sublimation Heat Press Transfer FilmThe SC-819 sublimation heat press transfer film is suitable for screen printing, and the printing surface is a fog-like, matte finish effect. This makes it ideal for co-heat transfer of printing plants

-

- S-08 Heat Transfer Vinyl FilmThe S-08 heat transfer vinyl film has the best color printing effect among all of our adhesive films, and is the most suitable for color printing and screen printing.

-

- S740 Matt Heat Transfer FilmThe S740 matt heat transfer film is a newly developed model. We adjusted the coating formula and added two new materials, based on a previous product, and eventually developed the S740 adhesive film with a high performance.

Xinhe is a transfer Vinyl film manufacturer that could provide customers transfer materials with excellent printing performance, and it is specialized in the garment accessories industry and heat transfer industry. A fine transfer material will ensure their qualities from release force, tensile strength, aging strength and other details.