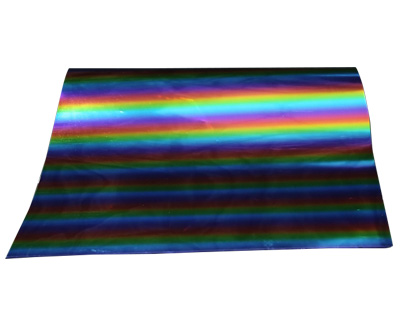

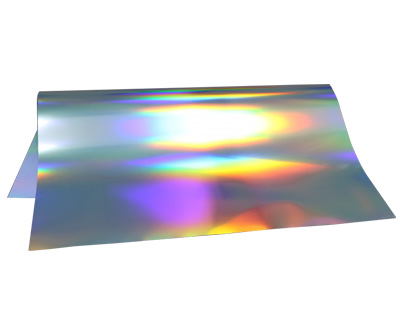

Holographic Heat Transfer Vinyl

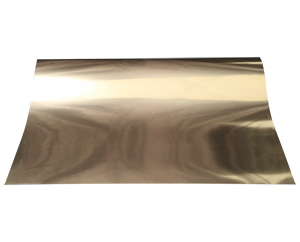

The heat transfer foil features a metallic effect after heat transfer, and is widely used in decorative labels, main labels, and promotional materials.

This heat transfer foil is a cold peel model, and needs to be cooled before being torn off after the heat transfer process. Users can set it aside to cool down, and work with the next work piece, which ensures a more flexible production period and requires less people for use.

This transfer foil is one of our most popular products, and features a stable performance and outstanding quality.

- Printing types: only for screen printing

- Printing inks: oil based ink, water based ink, thermosetting ink

- Coating techniques: powder scattering, liquid adhesive coating

- Printing Equipment: automatic or semi-automatic printing press for screen printing

- Thickness: 50um, 75um, 100um;

- Size information: 39×54cm, 64×48cm, 50×70cm or customized;

- Heat transfer temperature: 150 degree or depending on the adhesive or hot melt powder melting point;

- Heat transfer time: 12 seconds;

Note: Customers can choose different film thicknesses based on the different material and fabric applications, or the melting point of inks and adhesives.

-

- R1 Reflective Transfer FilmThe reflective transfer film is a reflective material formed by combining a reflective layer of glass beads and PET materials. Patterns are reflective after heat transfer

-

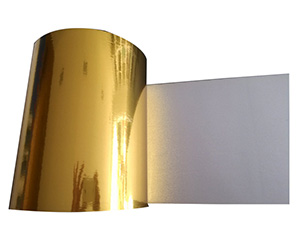

- Metallic Heat Transfer FoilThe golden/ silver foil look metallic transfer film is only appropriate for screen printing. It is a cold peel type, and needs to be cooled before being torn off after the heat transfer process.

-

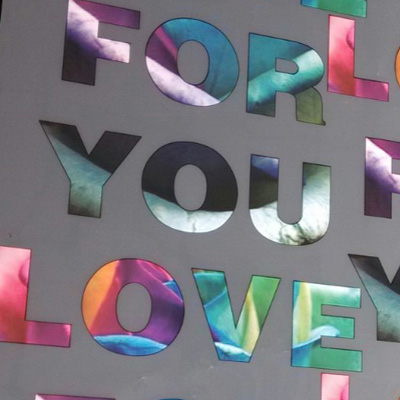

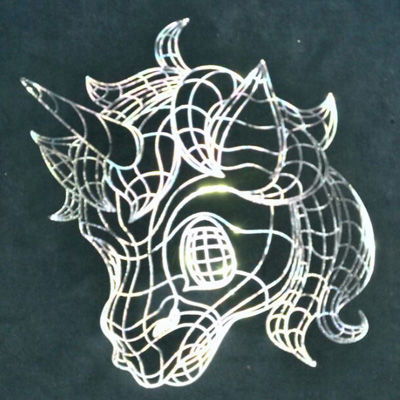

- CAD-CUT HTV (Heat Transfer Vinyl) Xinhe’s heat transfer lettering film is a special film that has been printed in a variety of coatings and ink colors. Customers need only laser cut the film into their desired design with no other printing process

-

- Cold Peel Transfer PaperThe cool peel transfer paper is easier to cut than transfer film, making it better for shipping marks with single or spot color. As a care label only needs to print a single color, cool peel transfer paper is the best type.

-

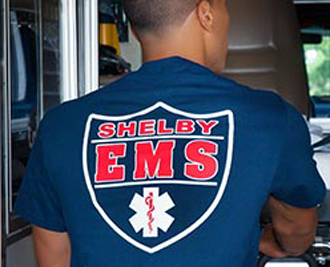

- Hot Peel Transfer Paper The T-65R transfer paper is a hot peel type, and must be quickly torn off after pressing. The logo appears as a matte finish after the heat transfer. This kind of transfer paper is suitable for shipping marks with single

Xinhe is a transfer Vinyl film manufacturer that could provide customers transfer materials with excellent printing performance, and it is specialized in the garment accessories industry and heat transfer industry. A fine transfer material will ensure their qualities from release force, tensile strength, aging strength and other details.